Advanced fleet planning and charge management strategies with the BetterFleet platform accelerate delivery of zero emissions outcomes

A Fleet Charged with a Challenge: Going Electric

Contributing to an overall target of net-zero emissions by 2045, the state of Victoria in Australia has committed to purchasing only Zero Emission Buses (ZEB) from 2025 onwards. To kick-start this transition, understand the challenges and foster industry collaboration, the Victorian Government launched a ZEB Trial with $20 million in funding for 50 buses throughout the state.

As part of this initiative, nine electric buses and the associated charging infrastructure were funded for the bus depot in West Footscray, serving the inner western suburbs of Melbourne. With the funding approved and Australian-made electric buses from Volgren going into production, focus turned to the next big challenge: planning the infrastructure installation and charging schedules in a way that facilitated efficient operations while avoiding a grid upgrade and maximising government funding.

To uncover the right charge management strategy for the depot, the Evenergi team worked in collaboration with Transit Systems, operator of the vehicles providing service at the West Footscray depot, in addition to thousands of buses throughout Australia.

A Data-Driven Plan

To get an accurate understanding of how much time each vehicle would need to charge upon returning to the depot, different route schedules had to be accounted for. Route data was imported into Evenergi’s fleet planning and management software, the BetterFleet platform, and analysed to provide detailed insight into the amount of energy each 348kWh vehicle would consume and need to replenish before hitting the road again.

The existing grid infrastructure at the West Footscray depot is able to support a limited number of kilowatts (kW) of overall power demand, and existing equipment at the site was already utilizing up to 75% or more of the available capacity throughout the day. This left an even more limited amount of capacity that could be dedicated to charging buses (minus additional safety margins), only available at certain times when not needed for offices, workshop, bus wash and other onsite facilities.

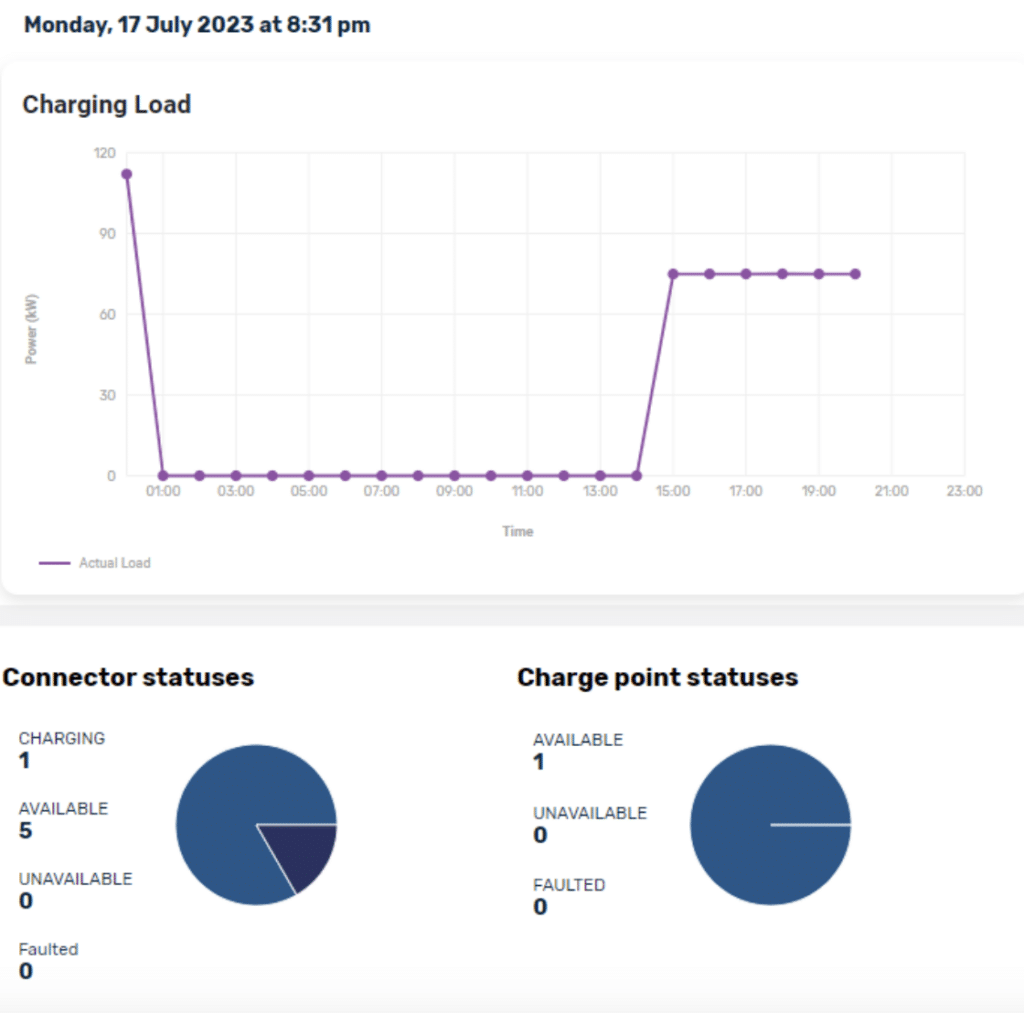

Example from BetterFleet scenario modeling results

With robust energy modeling capabilities, the BetterFleet platform enabled the team to quickly look at different charging schedules, compare the grid impacts of using different charge rates and times, and hone in on a smart charging plan that met operational needs while keeping overall energy consumption under required thresholds.

If a simplistic approach had been taken without a smart charging strategy, power consumption could have easily exceeded the kW threshold and triggered a grid upgrade. An upgrade to the grid equipment providing power to a depot can come with significant cost and lengthy timelines that may entail installation of hardware such as transformers and switchgear, in addition to adding new transmission lines that require trenching along streets and footpaths.

Instead, a plan was formulated with the BetterFleet platform that used existing grid infrastructure by keeping overall power demand under the limits while ensuring each bus would be charged sufficiently to meet its routes for the day. With an informed plan in hand, the Victorian Government was able to push implementation forward with confidence before breaking any ground. This helped to streamline the deployment of electric buses at the West Footscray depot in addition to lowering upfront cost, getting the state of Victoria one step closer to their goal of zero-emissions by 2045.

“Zero emissions buses are a key part of our plan to decarbonise transport and meet Victoria’s world-leading emissions reduction targets of 75-80 percent by 2035 and net zero by 2045.” – Minister for Climate Action Lily D’Ambrosio

Putting the Plan into Action

Establishing a strategic charging plan provided the necessary inputs for BetterFleet Manage, the charge management system now used on a daily basis to manage the depot’s 160kW Kempower charging system with 3 dual-port dispensers, providing 6 charging plugs distributing power to the new electric buses. Data since the vehicles’ deployment in May 2023 has shown an average charge time of 1 hour 50 minutes per bus and maximum power demand has remained underneath the threshold.

Taking into account power availability at different times, route schedules and overall grid infrastructure limitations, the BetterFleet charge management system dynamically adjusts charging in response to site loads throughout the day and maximizes use of available capacity.

Transit Systems CEO Michael McGee said the transport industry is undergoing a remarkable transformation, with technology further accelerating the decarbonisation of cities.

“Getting more passengers on public transport remains our priority as it is the most effective way to reduce a city’s emissions. By creating a public transport network that people want to use, it makes investing in the right technology even more valuable. We’re proud to work with industry leaders to provide solutions to our Government partners and customers to provide a seamless and more sustainable service to the community,” he said.

With a cloud-based, self-service portal, West Footscray depot managers can see the real-time status of their chargers and vehicles, control chargers remotely, and adjust charging schedules as needed. By using an advanced charge management platform, fleet supervisors can also receive alerts with diagnostics information to quickly resolve issues, and access reports on vehicle and charger performance, including odometer readings, emissions reduced, and energy consumed.

With the BetterFleet planning and charge management platform, Transit Systems can take advantage of operational data to continuously improve the planning and operations of their electric bus fleet, helping the state of Victoria stay on track to meet their zero-emission vehicle goals.

“This is another significant milestone for Evenergi and the public transport community, as one of the first bus depots in Australia actively using smart charge management software for a fleet of electric buses,” said Dan Hilson, Evenergi CEO. “We look forward to continued collaboration with Transit Systems and the Victorian Government at the forefront of the transition to zero-emission fleets.”